Push-In Plus Terminal Blocks

lastupdate: 2016/04/02

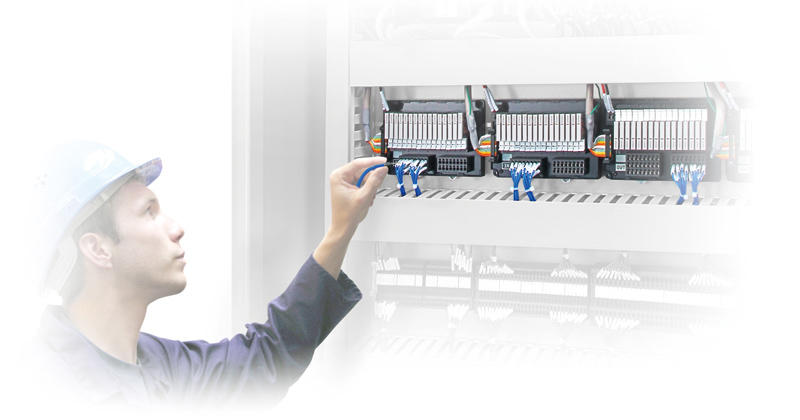

1.Push-in Terminals for Greatly Reduced Wiring Work

Have you ever thought that reducing wiring work would greatly reduce the overall work for control panel manufacturing?

Screw terminals require a lot of work, including loosening and removing screws, attaching terminals, and tightening screws, not to mention the need for retightening during manufacturing, shipping, and installation. You may have felt that wiring with screw terminals is troublesome.

To free workers engaged in control panels from this trouble, OMRON has used Push-in Terminal Blocks for our control panel products.

They are also designed with enhanced workability compared with conventional push-in terminal blocks.

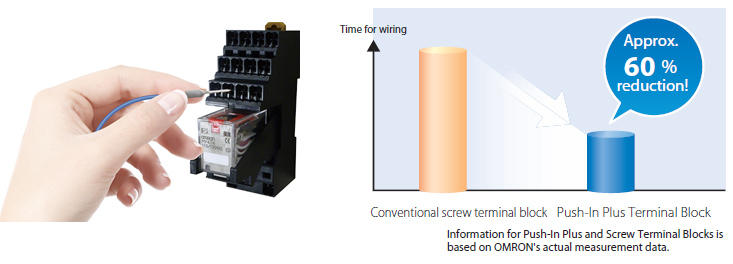

2.Push-in Terminals Have a Large Effect on Reduction in Wiring Work

Push-in terminals allow you to connect a wire simply by inserting it.

By reducing amount of work compared with conventional screw terminals, Push-in Terminal Blocks reduce wiring work by approximately 60%.

*Based on OMRON's actual measurements.

Because there are no screws, no screwdriver is required to tighten screws.

3.Retightening Work after Transport Shipping and after Installation Also Eliminated

Using screw terminals always involves retightening work.

On average, screw terminals need to be retightened at least three times: for production manufacturing , for shipping , and for installation.

Because products with push-in terminal blocks have no screws, they can eliminate retightening work.

Tests Simulating Vibration in the Installation and Shipping Environments

4.Wiring Bare Wires (Solid or Stranded) without Using Ferrules Also Possible

When you also want to reduce the work of crimping ferrules, you can connect not only solid wires but also stranded wires.

(For stranded wires, you must insert a screwdriver into the release hole.)

5.What are Push-In Plus Terminal Blocks?

Even in Europe and America, where screwless terminals are common, push-in terminals are still just coming into use.

The reason has been the stiff springs that hold the wires, which make it difficult to insert wires.

That is why OMRON developed new Push-in Terminal Blocks that achieve both less insertion force and firm wire holding ability. Because they are so innovative, we call them Push-In Plus Terminal Blocks.

Have you ever plugged an earphone into your music player or smartphone?

Almost everyone is comfortable inserting something that easily.

The feeling of inserting a wire into an OMRON Push-In Plus Terminal Block is just like the feeling of plugging an earphone into a earphone jack.

Less insertion force makes the work of wiring tens or hundreds of wires easier and reduces the stress on the wiring operators .

Insert Wires as Easily as an Earphone Jack

6.Easy Insertion, Even for Thin Wires

With conventional push-in terminal blocks, the stiff springs often cause thin wires to bend, preventing the worker from inserting them.

The less insertion force of OMRON Push-In Plus Terminal Blocks means that even thin wires can be inserted easily.

Easy Insertion, Even for Thin Wires

7.Push-In Plus Terminal Blocks: Easy Insertion and Firm Wire Holding Ability

It is well-known that push-in terminal blocks hold wires with springs.

Therefore, there is a tendency to think that easy insertion means a weak spring and that a weak spring means poor wire retention.

OMRON worked on developing spring materials and shapes for Push-In Plus Terminal Blocks and achieved both easy insertion and firm wire holding ability.

Pull Up a Heavy Object

8.You Can Leave the Screwdriver Inserted to Work with Both Hands

If you do not use ferrules, you must insert a screwdriver into the release hole in order to connect stranded wires.

If you can leave the screwdriver in the release hole when doing this work, you can work with both hands on the wires and make the wiring work easier.

With a clamp terminal, this is a matter of course, but with conventional push-in terminal blocks, the inserted screwdriver could come out.

OMRON's Push-In Plus Terminal Blocks can securely retain a screwdriver inserted into the release hole.

Screwdriver Is Held to Leave Both Hands Free to Work.

9.Easy Crossovers Too

When the same products are installed side by side, terminals with the same function on those products may be connected with crossovers.

With screw terminals, two wires are often wired to the same terminal, but with push-in terminals and other screwless terminals, inserting two wires into one hole is almost never recommended.

Therefore, many cases occur in which crossovers cannot be used with screwless terminals.

With OMRON's Value Design product group, Terminal Blocks have two terminals each with the same function when crossover is assumed.

Comparison of the Work Required to Wire Crossovers

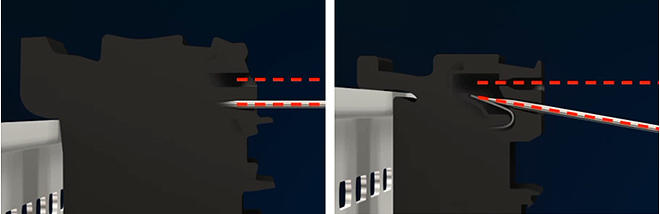

10.Angle for Screwdriver Insertion into Release Holes

With common push-in terminal blocks and clamp terminals, the screwdriver is inserted perpendicular to the terminal hole, so the screwdriver blocks the worker's line of vision and this makes the terminal insertion holes hard to see.

With OMRON's Push-In Plus Terminal Blocks, the screwdriver is inserted at an angle. This enhances the visibility of the terminal insertion holes, so the work is easier.

Push-In Plus Terminal Blocks Do not Block the Worker's View During Wiring.